-

Adhesives & Jewelry Glues

Adhesives & Jewelry Glues

-

Beading, Stringing & Knotting Tools

Beading, Stringing & Knotting Tools

-

Bench Blocks, Bench Pins, Pads & Anvils

Bench Blocks, Bench Pins, Pads & Anvils

-

Bracelet Tools

Bracelet Tools

-

Bulk Magnets

Bulk Magnets

-

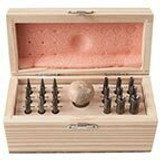

Burnishers & Stone Setting Tools

Burnishers & Stone Setting Tools

-

Calipers & Gauges

Calipers & Gauges

-

Cutters, Shears & Jewelers Saws

Cutters, Shears & Jewelers Saws

-

Cutting Lubricants

Cutting Lubricants

-

Drills, Bits & Hole Punches

Drills, Bits & Hole Punches

-

Enameling Tools & Supplies

Enameling Tools & Supplies

-

Etching & Engraving Supplies

Etching & Engraving Supplies

-

Flex-Shaft System & Accessories

Flex-Shaft System & Accessories

-

Hammers & Mallets

Hammers & Mallets

-

Jewelry Packaging & Displays

Jewelry Packaging & Displays

-

Jewelry Pliers

Jewelry Pliers

-

Jewelry Resins & Clays

Jewelry Resins & Clays

-

Jewelry Soldering Tools & Supplies

Jewelry Soldering Tools & Supplies

-

Kumihimo Tools

Kumihimo Tools

-

Leather Jewelry Making Tools

Leather Jewelry Making Tools

-

Looping & Mandrel Pliers

Looping & Mandrel Pliers

-

Loupes, Lights & Magnifiers

Loupes, Lights & Magnifiers

-

Memory Wire Pliers & Cutters

Memory Wire Pliers & Cutters

-

Metal Stamping Tools

Metal Stamping Tools

-

More Watch & Jewelry Tools

More Watch & Jewelry Tools

-

Needles, Conditioners & Bead Looms

Needles, Conditioners & Bead Looms

-

Nylon-Jaw Pliers

Nylon-Jaw Pliers

-

Organizers/ Storage for Jewelry Parts/ Tools

Organizers/ Storage for Jewelry Parts/ Tools

-

Oxidizers, Inks & Sealants

Oxidizers, Inks & Sealants

-

Ring-Making Supplies

Ring-Making Supplies

-

Riveting Tools

Riveting Tools

-

Safety Glasses & Safety Gear

Safety Glasses & Safety Gear

-

Shaping & Polishing

Shaping & Polishing

-

Templates & Center Locator

Templates & Center Locator

-

Tweezers

Tweezers

-

Vises & Clamps

Vises & Clamps

-

Wire Working Tools

Wire Working Tools

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Gray Plastic Clipcard, Surgical Steel Print, 1.5x2" (100 Pieces)

$5.25See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item.Questions? E-mail us for friendly, expert help! -

Magnet, Round, 18mm (35 Pieces)

$9.67Which Glue is Best? For the most durable bond, we almost always recommend epoxies rather than other types of glue, but it depends on a few factors... Check out the options, plus tips for successful glue bonds, on our Adhesives and Jewelry Glues page. See... -

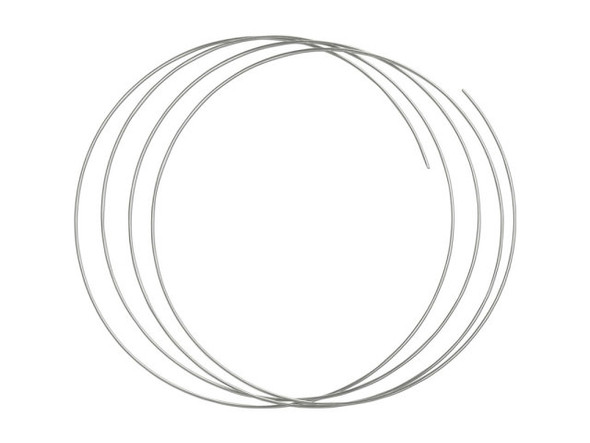

22ga Beadalon Stainless Steel Memory Wire Coil, Necklace, 1oz (ounce)

Beadalon$6.89Make quick and easy bracelets and necklaces! String your beads, then glue on a memory wire end, or use durable round-nose pliers to twist each end into a loop. (Optional: Add dangling beads or charms to looped ends.) Make lacy netted chokers... -

EURO TOOL Adhesive, Super New Glue (Each)

EURO TOOL$2.49Which Glue is Best? Check out all the options, plus tips for successful glue bonds, on our main Adhesives and Jewelry Glues page. See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this... -

The Beadsmith Bead And Pearl Knotting Tweezers

The Beadsmith$2.97Make your next jewelry-making project a breeze with The Beadsmith Bead and Pearl Knotting Tweezers. Say goodbye to frustrating knots and frayed threads, as these tweezers feature an incredibly fine point that allows for easy and precise knotting... -

Black Plastic Clipcard, Blank, 1.5x2" (100 Pieces)

$5.60See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item.Questions? E-mail us for friendly, expert help! -

22ga Beadalon Stainless Steel Memory Wire Coil, Bracelet, 1oz (ounce)

Beadalon$9.29Make quick and easy bracelets and necklaces! String your beads, then glue on a memory wire end, or use durable round-nose pliers to twist each end into a loop. (Optional: Add dangling beads or charms to looped ends.) Make lacy netted chokers and... -

Thompson Translucent 80-mesh Enamel for Metals - Peppermint Green, Sample (Each)

Thompson$1.60Enameling Tips:Enamel is durable, but not totally infallible. Handle finished pieces with care.Do all metal shaping, stamping, punching, etc. before adding enamels.Thoroughly clean your metal before enameling. Penny Brite works great!Before sifting... -

Beadalon Gold Plated Memory Wire End, 5mm - Gold Plated Steel (12 Pieces)

Beadalon$1.22See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Thompson Translucent 80-mesh Enamel for Metals - Aqua Blue, Sample (Each)

Thompson$1.60Enameling Tips:Enamel is durable, but not totally infallible. Handle finished pieces with care.Do all metal shaping, stamping, punching, etc. before adding enamels.Thoroughly clean your metal before enameling. Penny Brite works great!Before sifting... -

Brass Sheet, Floral Pattern #64-999-4285

$5.61See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

The BeadSmith Kumihimo Braiding Disk (Each)

The Beadsmith$4.47See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

The Beadsmith No Tangle Flexible Plastic Thread Bobbins For Kumihimo Or Macrame 1 7/8 Inch

The Beadsmith$3.95Looking for an easy and hassle-free way to store your Kumihimo or macrame thread? Look no further than The Beadsmith's No Tangle Flexible Plastic Thread Bobbins. Our patented locked design ensures that your thread stays put and tangle-free, while the... -

Blazer Micro Torch, Butane (Each)

$55.25See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Brass Sheet, Pebble Pattern (Each)

$5.28See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Flocked Bag, 4x3" - Black (12 Pieces)

$3.00See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Organza Drawstring Bag, 3x4" - Champagne (10 Pieces)

$2.43See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

The Beadsmith Lightweight Kumihimo Round Disc Disk For Japanese Braiding and Cording

The Beadsmith$3.27Ready to take your jewelry-making skills to the next level? Look no further than The Beadsmith Lightweight Kumihimo Round Disc Disk for Japanese Braiding and Cording. This Japanese-made disk is a game-changer for crafters of all skill levels, featuring... -

22ga Beadalon Stainless Steel Memory Wire Coil, Anklet/ Lg Bracelet, 1oz (ounce)

Beadalon$6.69Make quick and easy bracelets and necklaces! String your beads, then glue on a memory wire end, or use durable round-nose pliers to twist each end into a loop. (Optional: Add dangling beads or charms to looped ends.) Make lacy netted chokers... -

Jump-Ring Device (Each)

The Beadsmith$2.16See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Sunshine Polishing Cloth (Each)

$9.50See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Beadalon Elastic Cord Needle (Each)

Beadalon$3.65The Beadalon Stainless Steel Elastic Cord Needle is designed to simplify threading beads onto elastic cord. Made from durable stainless steel, this tool holds the cord in place while you easily slide beads over it, saving time and frustration. Perfect... -

Beadalon Bead Reamer, Battery Operated (Each)

Beadalon$15.55The Beadalon Battery Operated Bead Reamer makes it easy to smooth and enlarge bead holes with precision. This handheld tool is designed for use on glass, stone, and ceramic beads, helping you create perfect fits for stringing and wire projects. Its... -

22ga Beadalon Memory Wire Coil, Oval Bracelet - Silver Plated Carbon Steel (Each)

Beadalon$4.67See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Adhesive, E-6000, 3.7oz - HZ* (Each)

E-6000$9.90Which Glue is Best? Check out all the options, plus tips for successful glue bonds, on our main Adhesives and Jewelry Glues page. See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this... -

EURO TOOL Jewelry Pliers, Mighty Crimper, 5" (Each)

EURO TOOL$13.91With this specialty crimping tool, you don't need as much pressure on the crimp beads as you may have used with other pliers. Too much pressure can damage the tips of crimping pliers, and may cause the crimp to cut through beading cable. Pliers... -

The Beadsmith Jeweller's Micro Pliers Bentnose Bent Nose

The Beadsmith$6.69Transform your DIY jewelry making experience with The Beadsmith Jeweller's Micro Pliers Bentnose Bent Nose! With a unique angled design, you can now reach the tightest spots with ease, eliminating hand and wrist fatigue. These pliers are perfect for... -

The Beadsmith Mini Travel Bead Design Beading Board Gray Flock W/ Lid 7.75 x 11.25 Inches

The Beadsmith$4.87Unleash your creative potential and bring your bead designs to life with The Beadsmith Mini Travel Bead Design Beading Board! This essential tool allows you to experiment with endless combinations of beads, without the fear of cutting your thread too... -

EURO TOOL Finger Pro 3/4" Tape (Each)

EURO TOOL$1.80See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

The Beadsmith Jewelry Fine Round Nose Micro Pliers

The Beadsmith$8.64Looking to elevate your jewelry making game? Look no further than The Beadsmith Jewelry Fine Round Nose Micro Pliers. With their tapered points, these pliers allow for precision work with even the finest gauges of wire. Whether you're a seasoned... -

The Beadsmith Simply Modern Series, Round / Concave Nose Pliers, 4.75 Inches Long

The Beadsmith$9.44Make your jewelry crafting effortless and precise with The Beadsmith Simply Modern Series Round / Concave Nose Pliers. Whether you're a beginner or an expert, these pliers are perfect for creating stunning and intricate jewelry pieces that will leave... -

Kato Polyclay, 2oz - Violet (Each)

$1.98Polymer Clay Basics Polymer clays are man made modeling materials that, once heat cured, become permanent and will not return to their original state. All are composed of the same basic components: plasticizers, resins, fillers and colorants. ... -

Kato Polyclay, 2oz, Metallic - Silver (Each)

$1.98Polymer Clay Basics Polymer clays are man made modeling materials that, once heat cured, become permanent and will not return to their original state. All are composed of the same basic components: plasticizers, resins, fillers and colorants. ... -

The Beadsmith Jewelry Wire Side Cutters, Nippers, Pliers

The Beadsmith$7.37Upgrade your jewelry-making game with The Beadsmith Jewelry Wire Side Cutters, Nippers, Pliers. With top-notch polishing and construction, these side cutters are perfect for cutting soft wire, including tigertail, accuflex, copper, and sterling, making... -

The Beadsmith Wire Looping Pliers - Concave And Round Nose

The Beadsmith$12.99Upgrade your jewelry game with The Beadsmith Wire Looping Pliers - Concave And Round Nose. Achieving flawless wire loops has never been easier thanks to their sturdy construction and easy-to-use design. These pliers are perfect for delicate wire or heavy... -

Beadalon Hard Needles for Wildfire Thread, 1.125 Inches Long, 10 Needles

BeadalonMSRP: $3.79$3.17Unleash your creative potential with our Beadalon Hard Needles, designed specifically for the artisan in you. These precision-crafted size 13 needles are the perfect companion for Wildfire thread, providing an exceptional solution for intricate beading... -

Beadalon Spool Tamer Tool (pack)

Beadalon$6.56The Beadalon Spool Tamer is an adjustable dispenser designed to keep wire, cord, and thread spools under control. It helps prevent tangles while allowing you to adjust tension for smooth dispensing as you work. Perfect for bead stringing, wire wrapping,... -

Copper Foil Tape, 5/16", 36-yards (Each)

$14.42See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Sharp Flush Cutter Pliers - For Cutting Beading Wire

Xuron$24.25Upgrade your crafting game with the Sharp Flush Cutter Pliers from Brand-Xuron. Perfect for cutting beading wire, incuding multi-strand flex wire - these pliers feature a lap joint construction and tapered tips that create clean cuts in your wire and... -

Beadalon Knot-a-Bead Tool (Each)

Beadalon$22.05The Beadalon Knot-a-Bead Tool helps you easily tie secure, evenly spaced knots between beads and pearls. Designed for both beginners and experienced jewelry makers, this tool is perfect for creating professional-quality knotted necklaces and bracelets... -

EURO TOOL Bottle, Flux Dispenser, 2oz. (Each)

EURO TOOL$3.56See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Wire Gauge (Each)

EURO TOOL$12.95See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Silver Solder, Hard, Medium Grade, Sheet, 0.25oz (Each)

$14.00Silver and gold jewelry is assembled using hard solders and a torch. Hard solders are alloys of silver or gold that melt at lower temperatures than the sterling or gold karat alloys being used to make the piece of jewelry. Rings & Things carries silver... -

Buffing Wheel, Medium Abrasive, 2-7/8 x 3/4" (pair)

EURO TOOL$8.46After removing firescale or other rough spots with this medium-grit abrasive buff, you may want to follow it with a muslin buffing wheel for a higher polish. Entanglement Warning: Keep hair, loose clothing, dangling jewelry, and beards away from the... -

Flocked Bag, 4x3" - Blue (12 Pieces)

$3.40See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Organza Drawstring Bag, 3x4" - White (10 Pieces)

$2.43See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Vintaj Metal Reliefing Block (Each)

Vintaj$4.05See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Beadalon Bead Reamer, Replacement Tips (Each)

Beadalon$4.31See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Boston Bottle with Dropper - 1 oz., Clear (Each)

$1.16This replaces the out-of-production #63-110-01-522 cobalt blue Boston bottle with dropper. See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. -

EURO TOOL EuroPunch Jewelry Pliers, Round, 1.25mm Hole, Replacement Pin (pack)

EURO TOOL$5.56See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL EuroPunch Jewelry Pliers, Round, 1.25mm, 18g, Hole (Each)

EURO TOOL$12.35See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Multi-Size Looping Pliers (Each)

EURO TOOL$14.75See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Gift Box, Cardboard, 3.5x1" (10 Pieces)

$6.63See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Kato Polyclay, 2oz - Beige (Each)

$1.98Polymer Clay Basics Polymer clays are man made modeling materials that, once heat cured, become permanent and will not return to their original state. All are composed of the same basic components: plasticizers, resins, fillers and colorants. ... -

Magnet, Rectangle, 8x24mm (35 Pieces)

$9.27Which Glue is Best? For the most durable bond, we almost always recommend epoxies rather than other types of glue, but it depends on a few factors... Check out the options, plus tips for successful glue bonds, on our Adhesives and Jewelry Glues page. See... -

Rubber Bench Block, 4x4x1" (Each)

$5.32See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

The Beadsmith Scoop Eez Long Tube Scoop - For Seed Beads and Delicas

The Beadsmith$2.49Are you tired of spending countless hours picking up small beads one by one for your jewelry-making projects? The Beadsmith Scoop Eez Long Tube Scoop is the solution you've been looking for! This stainless steel scoop saves you time by allowing you to... -

AccuLoop Round Nose Pliers (Each)

EURO TOOL$17.95See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item.Questions? E-mail us for friendly, expert help! -

EURO TOOL 4" Diamond Needle File Set (set)

EURO TOOL$13.65Shaping, Smoothing and Texturing Tools Clean your tools promptly after each use, so you can save the scrap silver and re-use it. It might not seem like much each time, but it can add up to a lot of saved money! Small screw-tight cosmetic... -

Wubbers Chain-Nose Jewelry Making Pliers (Each)

Wubbers$27.45Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

22ga Beadalon Memory Wire Coil, Oval Bracelet - Gold Color, Carbon Steel (Each)

Beadalon$4.47See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Beadalon Tassel Maker Tool (Each)

Beadalon$17.99This video by Beadalon demonstrates how to use their Tassel Maker. See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. -

Brass Sheet, Brush Swirl Pattern (Each)

$5.28See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Jewelry Pliers, Crimping, Standard, 5" (Each)

EURO TOOL$11.65With this specialty crimping tool, you don't need as much pressure on the crimp beads as you may have used with other pliers. Too much pressure can damage the tips of crimping pliers, and may cause the crimp to cut through beading cable. Pliers... -

Kaowool Fiber Blanket, firing pad, 5x6x1" (Each)

$6.88See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. -

Wubbers Round-Nose Jewelry Making Pliers (Each)

Wubbers$28.45Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

Baby Wubbers Bent Chain-Nose Jewelry Making Pliers (Each)

Wubbers$25.44Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

Baby Wubbers Round-Nose Jewelry Making Pliers (Each)

Wubbers$25.53Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

EURO TOOL Cup Bur, Wood Handle (Each)

EURO TOOL$7.17See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Flat Beadalon Memory Wire, Large Bracelet - Silver Plated Carbon Steel (.35ounce)

Beadalon$4.47See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Hobby Knife, Fit Grip (Each)

$5.54See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Mixing Cup, 1oz (10 Pieces)

$1.44See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Silicone Resin Stud Earring Molds (pack)

$0.96See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Stainless Steel 1/8" Bead Mandrel (Each)

$2.03See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Wubbers Bent Chain-Nose Jewelry Making Pliers (Each)

Wubbers$27.45Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

Wubbers Large Round Jewelry Bail Making Pliers (Each)

Wubbers$28.45Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

Wubbers Medium Round Jewelry Bail Making Pliers (Each)

Wubbers$28.45Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

3M Polishing Paper, Wetordry, 600 Grit (Each)

$1.94See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EasyCast 8oz Epoxy Kit - HZ* (Each)

Castin'Craft$12.95See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Beading Tweezers (Each)

EURO TOOL$3.95See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Cup Burr, Wire Rounder (set)

EURO TOOL$11.95See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Saw Blade, #2/0 (12 Pieces)

EURO TOOL$0.83See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Thread Burner (Each)

EURO TOOL$25.65See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Organza Drawstring Bag, 2x2.5" - White (10 Pieces)

$1.84See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Organza Drawstring Bag, 3x4" - Silver (10 Pieces)

$2.43See Related Products tab for products and projects that go with this item. -

Silicone Resin Pendants Mold (Each)

$3.71See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

The Beadsmith Jewelry Micro Pliers Duckbill Flat Nose

The Beadsmith$6.69Get ready to take your DIY jewelry-making skills to the next level with The Beadsmith Jewelry Micro Pliers Duckbill Flat Nose! These expertly crafted micro pliers are your secret weapon for flawless wire and sheet metal bending, narrow-spot reaching, and... -

The Beadsmith Jewelry Pliers, Round Nose, Chain Nose, Side Cutter

The Beadsmith$12.15Looking to elevate your jewelry-making game? Look no further than The Beadsmith Jewelry Pliers. This set of round nose, chain nose, and side cutters is perfect for any crafter, expert or beginner. With smooth and angled jaws, these pliers allow for... -

Wubbers Small Round Bail Making Pliers for Jewelry (Each)

Wubbers$23.95Gain access to thousands of free jewelry making tutorials and classes from Wubbers University with the purchase of a single pair of Wubbers pliers. See Related Products links (below) for similar items and additional jewelry-making supplies that are... -

22ga Beadalon Memory Wire Coil, Large Oval Bracelet - Silver Plated Carbon Steel (.35ounce)

Beadalon$4.54This silver-plated Memory Wire is pre-formed into a large oval bracelet size, measuring 3 inches in diameter with 20 loops. Memory wire is strong and flexible, designed to hold its shape without the need for clasps. Simply string on beads and finish the... -

6mm, 1/4", Gothic Numeric, Number, Metal Stamps Set (Each)

The Beadsmith$7.96See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Boston Bottle with Sprayer - 1 oz., Clear (Each)

$1.16See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Butane Micro Torch (Each)

$25.93New to torching? Don't worry! The packaging includes detailed instructions for lighting, flame adjustment, and refilling gas tank. This torch is incredibly easy to use, and has good safety features. See Related Products links (below) for similar items... -

Castin'Craft Jewelry Mold, 11 Gem Shapes (Each)

Castin'Craft$5.69See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Crystal FX Glue Syringes, Medium Viscosity - 4 pack (multi pack)

The Beadsmith$6.49Can also be used to fill bezels, bottles, vials and other small containers with perfume, essential oils or other liquids.See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item... -

Endless Loom Bands, 7", Clear (pack)

The Beadsmith$4.45How to use the Deb Moffett-Hall Endless Loom: How to Choose the Correct Endless Loom Bands: See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. -

EURO TOOL Flat File, 6", #2 Cut (Each)

EURO TOOL$17.55See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Fume Extractor (Each)

EURO TOOL$53.95Not a full ventilation hood, but great for small spaces!See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

EURO TOOL Screwdriver Set, 6 Piece, Economy (set)

EURO TOOL$2.21See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help! -

Ferric Chloride Copper Etchant Solution - HZ* (Each)

$27.42See Related Products links (below) for similar items and additional jewelry-making supplies that are often used with this item. Questions? E-mail us for friendly, expert help!